Duffield Timber has a long tradition of expansion and innovation, and 2022 will bring our biggest ever single investment. Our mill, warehouses and machinery are all being upgraded, allowing the next generation to provide a quality of service we have taken pride in for the past 60 years.

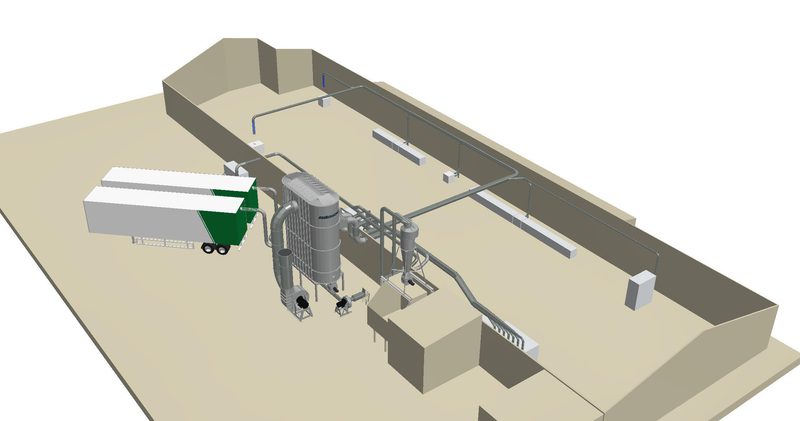

Our plan began in June 2021 when we took the decision to expand and improve our mill production. Work is already underway for the installation of a new SuperBlower extraction system in a much larger warehouse, which up until now has been used for stock storage. One the major benefits of this relocation is improving how we manage our waste.

Timber rippings will now be automatically cross cut off the back of the saw and fed straight into the shredder, rather than been transported around our site or being stored in our yard. This will ensure that we continue to use all our excess timber to either heat our buildings, be sold as firewood or shredded ready to be converted into biomass wood pellets, which we stock in our onsite Joinery and Woodworking Centre. This is in line with our sustainability policy and we will continue to ensure we are an environmentally considerate company.

The additional 70% floor space and increased extraction power of 65,000m³ per hour will give us the capacity to add another moulding machine to our line-up which will significantly speed up our production of cladding, decking and fencing. We will also upgrade one of our existing WEINIG Powermat 1200 machines to a 3000 model which will speed-up our feed rates to 60m per minute, an increase of 240% which will give us an overall feed rate of 85m per minute across the site. Our new WEINIG Powermat 3000 has semi-automated infeed and outfeed tables which will significantly aid our mill team.

To get the warehouse in shape for the change from storage to full-on mill production, we had to undertake a huge amount of renovation and works, including Asbestos removal, new cladding and roofing, and a polished concrete floor. All of these upgrades will prove their worth once our new mill is fully functional and operating at capacity.

Our next phase of works will see us installing a new office space and tool room, with a seamless transition from factory floor to workshop, making it ideal for our tool trolleys and transportation. Once ready we will begin the monumental task of transferring and installing our equipment, with the new mill being ready for action next year.