Bespoke Machining

As specialists in the industry, we machine bespoke timber products including cladding, fencing, decking and joinery to the highest possible standard.

In recent years our machining facility has received great investment and houses state of the art hardware and software.

Two Weinig PowerMatt 1200 moulding machines provide quick change over tooling, capable of producing a glass like finish, each with a throughput of up to 30 metres per minute.

Two laser guided ripping lines feed the production lines with precision blades and computerised waste optimisation.

Fully automated cross cutting line with defecting technology ensures quality and accuracy when it comes to requiring finished components.

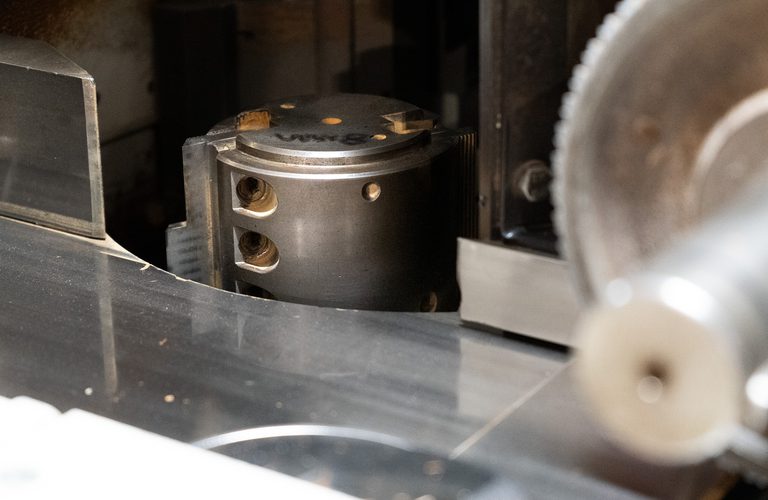

Our in house tool room holds thousands of catalogued and coded profiles that are maintained by a full time engineer. We produce CNC templates and grind our own cutters on site so we are able to match specific customer profiles exactly or provide a totally bespoke profile service.

State-of-the-art machinery, combined with decades of industry experience and rigorous quality control, underpins our reputation as a trusted specialist in machined timber components. Every process is carefully monitored to ensure precision, consistency and reliability, delivering products that meet exacting standards and perform as specified, time after time.

If you are looking for a the complete package, Duffield Timber offers a full range of factory applied coatings, finishes and fire retardant treatments:

Looking for bespoke machined products? Get in touch with our team to discuss your next project.

Contact us