Starting as a felled tree, your wood goes on quite a journey before arriving as a finished product. Allow our team of timber experts to explain the entire process!

Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local DIY store, a piece of furniture or some cladding, decking or fencing.

Timber is one of the world’s oldest building materials, but is still as incredibly valuable and versatile as ever. Curious about the various stages involved in its journey to your local store?

Stage 1: Tree selection and harvesting

It all starts in the forests. From the sub-zero wildernesses of Russia to sun-baked canopies of West Africa, many types of trees exist and thrive all over the world.

At our woodworking centre, you’ll find temperature species including European Oak, frost-hardy woods like Siberian Larch as well as tropical hardwoods such as Zebrano and Wenge. Did you know that there are over 73,000 species globally? Perhaps even more fascinating is that there are still around 9,000 yet to be discovered!

What we do know, however, is that 4,000 species are commonly used for timber. Some are eye-wateringly expensive — such as ebony — whilst others, like pine, are more budget friendly. It all boils down to market forces: the abundance of a certain type of tree and levels of consumer demand. Performance and visual aesthetics can affect how valuable a species is deemed to be.

Whichever species it is, they are selected by forest management companies based on age, health and sustainability and felled using an axe, hand saw or chainsaw. Then, they are transported by lorry and stored in a dedicated facility.

Sustainability in wood harvesting

Since trees can be replanted, wood is 100% renewable — but this doesn’t mean it’s 100% sustainable. If trees are harvested faster than they can be replenished, then it’s decidedly unsustainable.

Research has indicated that the world has around 3.04 trillion trees, with 15.3 billion chopped down every year. Global tree count has fallen by 46% since the beginning of human civilization.

Not all of these go on to become timber, sadly — many are cleared for agriculture. It gives you an idea of the scale of the forestry industry and the importance of sustainability.

It’s incumbent on timber purchasers to ensure the wood they source comes from well-managed woodland where stocks are managed appropriately. There are also certification schemes so consumers can be certain of the environmental and ethical sustainability of the wood they buy — two of the most popular are FSC® or PEFC.

Over on another blog, we’ve written in a little bit more detail about the sustainability of timber as a construction material.

Stage 2: Initial processing

After being chopped down, the wood is transported to a dedicated lumber drying mill. These types of facilities can be huge — they’re where the felled tree begins its real transformation to becoming a quality timber product. A number of key things take place:

- Debarking — as the name suggests, the wood is removed of its outer bark. This is done using a specialist machine. The by-product is used for biofuels or wood mulch.

- Head rig sawing — using a head rig (also called a head saw), the debarked trees are cut into rough sawn shapes and sizes, called ‘cants’. These are usually long, flat planks — an ideal shape for further processing. Here, computerised systems are involved to ensure maximum yield from each tree.

- Edging and trimming — edging involves removing irregular edges and defects from the sawn pieces of wood using chisels and routers. Trimming refers to squaring off the sides and ends of the timber, preparing it to be sorted.

- Rough sorting — the wood is categorised based on end use; either unseasoned (also known as ‘green’) or dry.

- Stickering — if the wood is destined to be dry, it is stacked with spacers, also called ‘stickers’. These allow air circulation, facilitating the drying process. Green wood skips this stage.

- Drying — this is crucial; too much moisture in the wood can cause instability in the finished product, like shrinking and swelling. Drying is usually done in kilns — a purpose-built ‘oven’ where air circulation, humidity and temperature can be controlled. The aim is to evaporate moisture content out of the wood.

Stage 3: Planing and grading

Planing: Depending on end application, the wood will then have its surface smoothed to remove any imperfections. This gives it uniformity in width and thickness. This is done using specialised machinery that removes a small amount of wood with each pass. Sanding tools can also be used, such as belt sanders and disc sanders.

Grading: The wood is sorted according to its quality. Common characteristics involved are appearance, strength and durability — the wood may need to be of a specified quality or grade to make it to market for certain application. The characteristics of each piece of wood will be assessed.

Grading timber by appearance — ‘unsorted’ and ‘sawfalling’

In the timber industry, woods are typically graded 1-6. You may often see this displayed instead with Roman numerals: I, II, III, IV, V and VI.

Grades 1, 2 and 3 (I, II and III) are the highest grades, often collectively referred to as ‘unsorted’. 1st grade boards are virtually clear with sound pin knots; 2nd grade can contain 5–6 sound or dead knots up to the size of a 5 pence piece; 3rd grade boards can contain up to 10–12 mixed size knots up to 10p size, some of which can be dead or loose.

Grades 4, 5 and 6 (IV, V and VI), collectively referred to as ‘sawfalling’ allow for more ‘defects’ — you may see frequent knots and some larger knots up to the size of a 50p.

Stage 4: Machining, turning and treatments

Whatever the end use of the timber, it’s at this stage that it will begin to take real shape. It’s now that the wood will be fashioned into a finished product and ready to be sold.

After being shipped to a dedicated facility, wood intended for use as cladding, fencing or decking will be machined to a certain profile using specialist equipment; wood intended for use in furniture will be fashioned into various shapes and components, with all the required intricate cuts and joins.

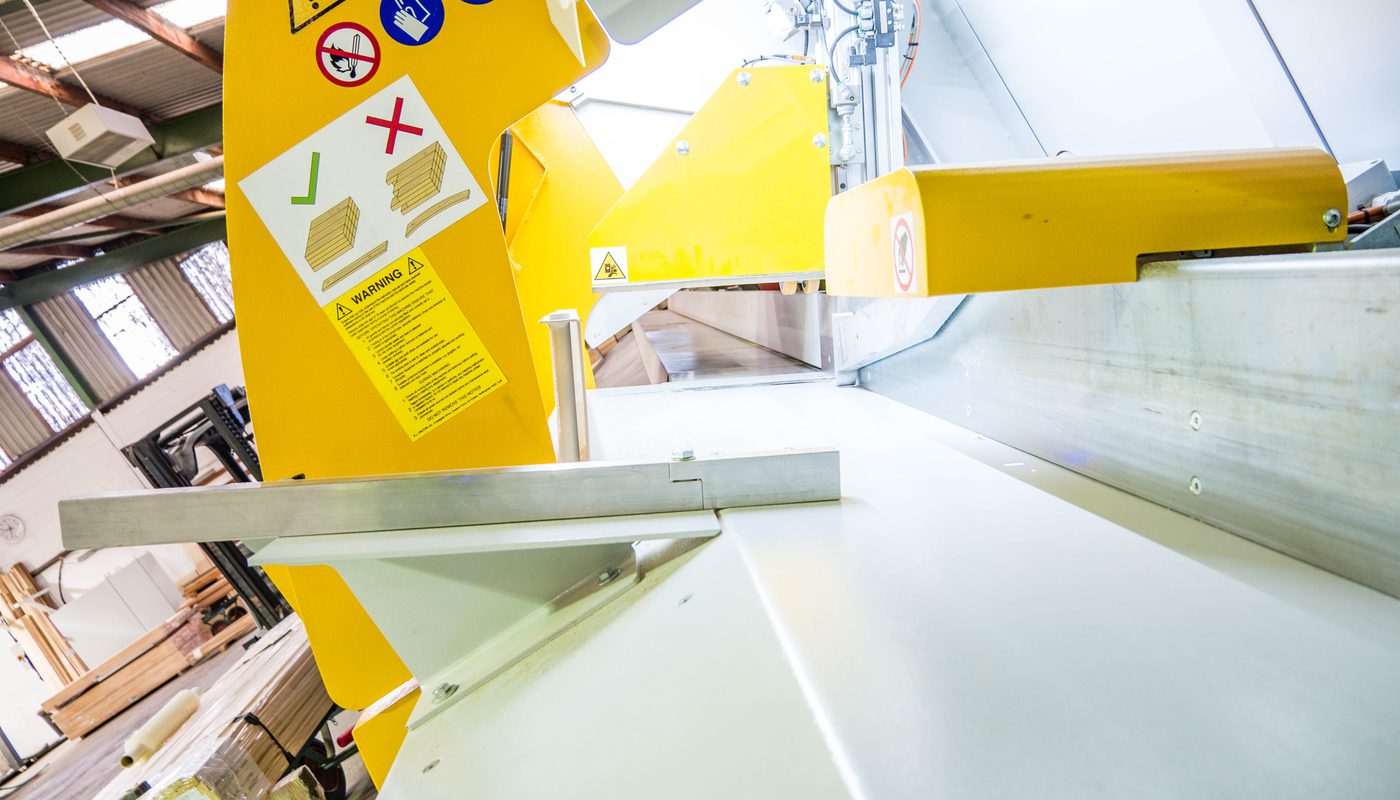

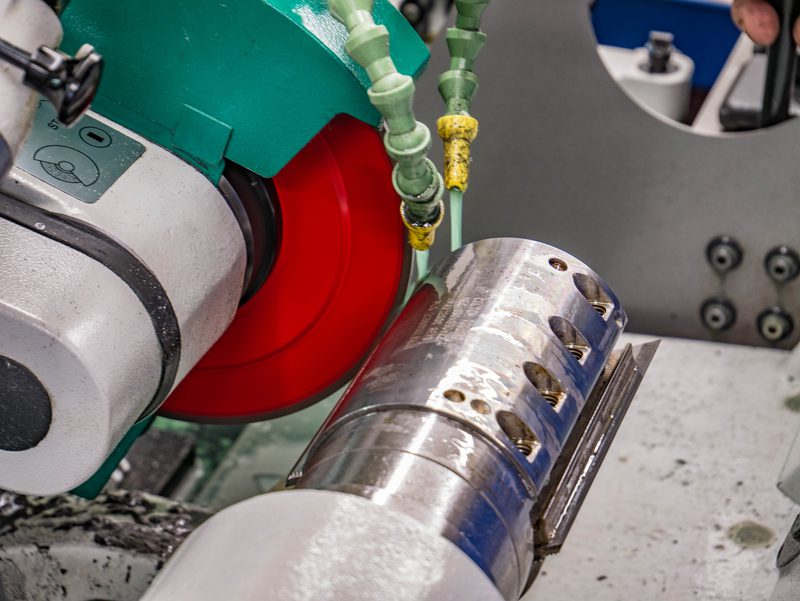

At our machining and finishing facility, we have two WEINIG PowerMat 1200 moulding machines, a WEINIG Raimann (with laser guided waste-optimisation technology), a WEINIG Rondamat grinder and a Salvador automatic cross-cutter (with defect detection).

Some products, such as featheredge cladding and oak beams, are handled using bandsaws.

WEINIG PowerMat 1200 moulding machine, containing eight heads.

Salvador automatic cross-cutter (with defect detection).

At this stage, any stains, varnishes and other treatments will be applied to the product, the aim usually to bolster the product’s appearance and performance. Factory treatments, such as heat treatment or pressure treatment, may be applied at this stage to enhance the timber’s appearance and outdoor performance, as well UV and fire retardant treatments.

Stage 5: Distribution and retail

If the product isn’t being sold by those machining it, it will be packaged and distributed to a retailer’s warehouse or physical retail site, such as a DIY store. At this point, the timber products can be purchased online or in person by tradespeople and members of the public.

Got more questions?

As one of the UK’s leading timber importers and machinists, we know a thing or two when it comes to wood! Drop our team a message using the Get in touch button below — we’d be delighted to hear from you.

Whilst you’re here, you might also like to take a look through our range of quality sawn timber, cladding, fencing and decking!