From the modest garden shed to ostentatious feats of architecture, cladding is at home on almost any type of building. It’s a timelessly popular way of creating a beautiful, natural exterior finish.

Two of the biggest choices when planning project are the species (the type of tree that the timber originated from) and profile (which determines the way the cladding pieces fit together). Let's walk through the best options.

The best type of timber for exterior cladding: choosing a species

Softwoods like western red cedar, Siberian larch, Alaskan yellow cedar and Douglas fir are some of the most popular options for outdoor wood cladding. They perform the role of being naturally durable outdoors, dimensionally stable and attractive at a cost-effective price.

Also popular are thermally-treated softwoods like Thermo-pine, Thermo-Tulipwood and Thermo-ayous. When it comes to hardwoods, European oak is a perennial cladding favourite.

1. Western red cedar

- Colour: Varies; reds, pinks and dark browns

- Grain: Straight grain, medium-to-coarse texture

- Sourced from: British Columbia, Canada

A highly-durable softwood with stunning colour variation, western red cedar has become a wildly popular cladding timber in recent years. Many consider it to be the best species for cladding.

Lightweight, stable, decay resistant and with impeccable workability and finishing properties, this resinous species naturally repels the destructive forces foisted upon it by nature.

It doesn’t matter whether you’re wood cladding a house or the side of a large real estate property, Western Red Cedar is sure to be a high-performance, classy solution.

Colour: Pale yellow to a medium brownish colour

Grain: Distinctively strong grain; medium-to-fine texture

Sourced from: Siberia, Russia

Siberian larch’s heartwood can range from a pale yellow to a medium straw yellow in colour so, for a natural finish, this is a great timber to choose. It typically has a strong grain pattern with visible growth rings, so is sure to add a little character.

With great overall results when nailing and screwing, Siberian Larch makes for a highly durable, dense and stable exterior wood cladding material.

Siberian Larch is available in a number of grades, including 'unsorted', which is clearer with few small or no knots. The other grade is 'sawfalling', which allows for larger, more frequent knots. Not an altogether bad thing if you’re after that natural look!

A premier softwood, Siberian larch is right up there with western red cedar in terms of popularity. Both perform a great job outdoors — your choice will usually come down to personal preference for colour. We’ve actually written an entire blog post comparing the two!

3. Douglas fir

Colour: Light brown with hints of red; darker growth rings

Grain: Interesting, wild

Sourced from: British Columbia

Douglas Fir is an outstanding softwood and time-honoured cladding favourite. As with all timber species listed in this article, it boasts exceptional inherent resilience to those natural forces of decay it’ll encounter when used externally.

Fir boasts a wild, interesting grain with plenty of variety — great for adding some stunning natural character to your project. Not only that, but it’s also particularly strong and scratch resistant.

4. European oak

- Colour: Golden-brown; can vary

- Grain: Straight, with a coarse, uneven texture

- Sourced from: France

Boasting gorgeous golden brown colour and a characteristic straight grain, European Oak is a perennially popular hardwood cladding.

As tough as nails and with good natural durability, the beauty of this species can be enhanced by a stain or finish. European Oak stock imported into the UK has already been through the kilning, machining and finger-jointing process all prior to delivery.

As the boarding is glued and finger jointed, it can be supplied in longer, more stable 4.5m lengths. For smaller pieces, this product can also be edited free from defects.

Nailing and screwing can be a bit more difficult — so pre-drilling is advised. It’s also worth noting that Oak reacts with iron, so stainless steel nails or screws are your best bet.

For a beautiful, longer-length hardwood external cladding, European Oak is the one for you — timeclass classiness guaranteed.

5. Thermo-pine, Thermo-ayous & other heat-modified woods

Colour: Mid-to-dark brown

Grain: Generally straight; medium-to-fine texture

Sourced from: Central and West Africa, Baltic region and more

Looking for a darker type of timber cladding? Perhaps mimicking rare, tropical species like mahogany and teak — at a fraction of the price? Look no further than the heat-modified softwoods currently available.

Thermo-pine (also commonly known as ThermoWood) is probably the best known example. It starts life as softwood Scandinavian pine, with thermal treatment bolstering its stability and outdoor durability. Available in a wide range of profiles, Thermo-pine takes well to both screws and nails.

Then there’s Thermo-ayous. Sourced from the forests of central and west Africa, heat treatment bestows it with a gorgeous, clear-grade mid-brown colour. Be sure to also take a look at Thermo-tulipwood CAMBIA® — another heat-treated species with a magnificent clear-grade appearance and exceptional outdoor durability.

This is not an exhaustive list, of course. There are many other types of timber that also step up to the job of exterior cladding, such as Alaskan yellow cedar, but given their commercial availability and cost, you can’t go wrong with those we’ve just mentioned.

Exterior timber cladding profile types

Profile refers to how the wood is machined and determines how the cladding pieces fit together. Different profiles can provide different finished looks, and can even affect weather resistance and outdoor performance.

Two of the most popular cladding profiles for a modern, contemporary finish are undoubtedly V-groove and shadow gap. If you’re after something on the more rustic or traditional side, perhaps for a barn conversion, then featheredge is a solid choice. For an eye-catching decorative finish, rainscreen might be the one.

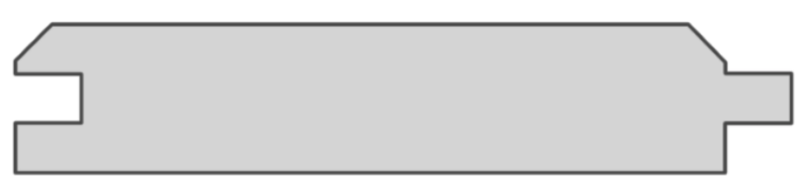

V-groove

From small household jobs to large-scale commercial projects, this versatile profile is possibly the most popular out there. V-groove is also known as tongue & groove V-joint or simply V-joint.

The boards slot together neatly and simply thanks to a tongue (the protruding section) and groove (the slot). It’s why profiles like V-groove are often referred to more generally as simply ‘tongue and groove’.

The fit of the boards forms a ‘V’ shape on the surface, providing a pleasing, faint shadow line between each. This results in a modern, clean, neat look and, much like Shiplap (mentioned later), has the ability to shield buildings from water — providing excellent weatherproofing.

V-groove works well for: any project where a smart, modern, clean look is desired. A real all-rounder cladding profile.

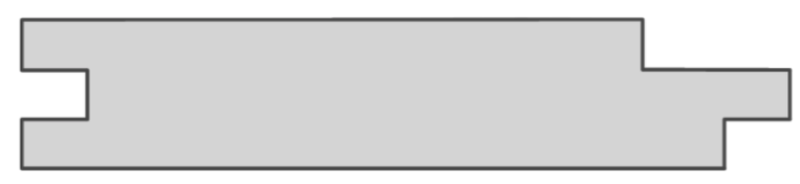

Shadow gap

For the architecturally-minded amongst you, look no further than this modern, stylish profile for a designer cladding option.

It has a similar tongue and groove fit to V-groove. But, because of the way it is machined, once these profile boards are put together you get a smart square 1cm gap, with sunlight or artificial lighting producing linear shadows across the cladding.

This type of profile is available in horizontal and vertical with secret nail variations also on offer, so fixings are hidden. The clean lines of the profile strike a very contemporary note.

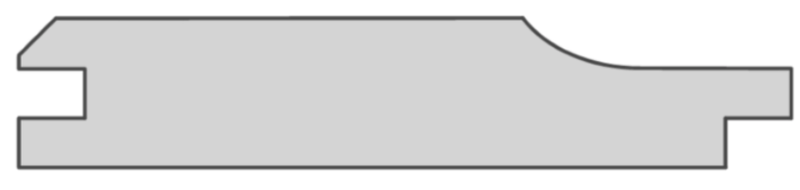

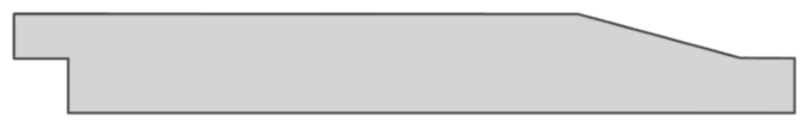

Featheredge is great for a traditional touch. Cut at an angle, featheredge’s overlapping boards are popular for large barn conversions, outbuilding renovations and old-style agricultural buildings.

Fitted horizontally, feather-edge is guaranteed to add a rural, rustic feel. It also offers excellent weather-proofing — this profile is also known as ‘weatherboarding’.

As well as being a secure and sturdy choice, feather-edge gives an element of freedom. The way the profile cladding is cut is to allow for an overlap, giving more control over how the finished result looks by allowing the fitter flexibility over the cover size.

Feather-edge works well for: a sturdy, rural-inspired, clean and weather-proofed look — such as barn conversions or garden sheds.

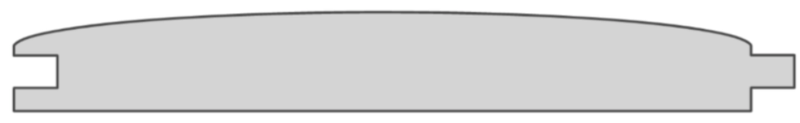

Shiplap

Another very popular profile, Shiplap shares similarities with V-groove and shadow gap — both have a tongue and groove fit. The key difference is the longer lip, which provides superior water protection.

This lip gives a pleasing, soft curved shape on the cladding surface; a popular, traditional choice often associated with rural settings. Ideal for invoking a sense of countryside charm, Shiplap is very popular for cladding sheds and other outbuildings.

Shiplap works well for: any cladding project where a slightly more traditional, rustic (yet still smart) feel is desired, such as a garden shed or outbuilding.

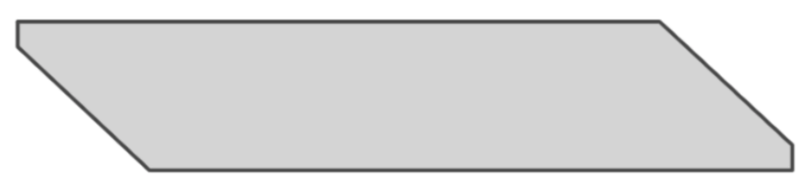

Rainscreen (or ‘splayed’)

If you’re looking for a contemporary, completely decorative finish, consider a rainscreen profile (also known as splayed, rhombus or open-jointed cladding).

This profile’s rhomboid-shaped boards are equally spaced, but aren’t interlocked or connected, meaning that they don’t provide total protection against the elements. That said, they provide a stunning, unique and clean architectural touch.

As such, this profile is best suited to design-first projects that are completely shielded from the elements. For more information about this interesting profile, check out our rainscreen cladding guide!

Rainscreen works well for: design-led projects seeking a contemporary, natural touch is desired.

Square-edged 'open' (single-width and mixed-width)

Similar to rainscreen, this is a modern, architecturally-forward 'open' profile, but with planed square edged boards. The 10mm gap creates a shadow line, defining the individual boards. This can be done with a single-width or in a mixed-width arrangement.

Rainscreen works well for: an eye-catching, design-forward contemporary project.

Half-lap

If you’re looking for a minimalist take on Shiplap, chamfered half-lap could be the ideal profile — it brings a little bit more subtlety whilst retaining a soft, sleek curvature.

Stable and performing well against moisture, this is a refined, understated profile for any horizontal exterior cladding project.

Once installed, the surface reveals a smooth finish with slim shadow lines; a versatile choice that fits into both the traditional and contemporary camp.

Halflap works well for: classic and contemporary cladding projects where a more subtle take on Shiplap’s curvature is required.

Log-lap

As the name hints at, log-lap’s aim is simple: to emulate the look of a log cabin. It features a tongue and groove fit, with each board having a curved surface.

This profile is popular with home improvers seeking to add some rural or ski-hut-style charm to a summerhouse, garden room or office.

This distinctly European profile can be provided in thicker boards to achieve a more pronounced log-like curvature.

Log-lap works well for: recreating the look and feel of a log cabin.

Vertical or horizontal?

Orientation is another key consideration. If you’re having some trouble making up your mind, check out our guide comparing vertical and horizontal cladding.

Some examples might also help you to decide… have a gander at some of our recent cladding case studies for ideas and inspiration. We’ve also written a blog about the latest timber cladding trends if you want to make a statement with your project.

Pricing up your project: how much does timber cladding cost?

Your project price depends on how much cladding you require (of course), the species of wood you choose and, to a lesser extent, the profile chosen. If you’re not installing it yourself, the cost of hiring a contractor needs to be factored in too.

Let’s say you’re working on a typical garden room (3.8 length x 2.4m width, 2.2m height). To clad all walls in a V-groove cladding profile and allow for an 8’ bifold door, you’ll need in the region of 22m² of cladding — but remember to allow approximately 10% for waste on top. The total required would be 24m².

In our DTC2 V-groove cladding profile, this would cost:

Western Red Cedar — approx. £1,488 (£62 per m²)

Alaskan Yellow Cedar — approx. £1,450 (£60 per m²)

Douglas Fir — approx. £1,260 (£52 per m²)

Siberian Larch (‘B’ and ‘A’ grade) — approx. £1,080–1,200 (£45–50 per m²)

Thermo-Pine — approx. £936 (£39 per m²)

Thermo-Ayous — approx £1,320 (£55 per m²)

Thermo-Tulipwood CAMBIA® — approx. £1515 (£63 per m²)

Note that this doesn’t take into account costs associated with hiring someone to install the cladding, if you’re not doing it yourself. Costs can vary, but a specialist cladding installation contractor can set you back in the £200 per day region.

Prices are correct as of December 2023 and don’t include VAT. For a solid cost estimate for your project, feel free to get in touch with our team of timber cladding experts!

Ready to get cladding?

Home improvers, contractors, architects, specifiers… we work with many customers across the UK. Explore some of our recent cladding projects for a flavour of how your space could be transformed with timber.

We stock a range of quality timber cladding in many of the world’s most beautiful, durable species — all sustainably sourced and machined to profile on-site by us.

If you’re just after some finishes and fixings, you’re in the right place too — we stock a range of specially selected wood stains, oils, angle beads, nails, screws, shingles and ridges.

To get your project started or discover the answer to any other questions, click the ‘Get in touch’ button below, email sales@duffieldtimber.com or phone 01765 640 564.