The type of wood you choose for your cladding project is one key consideration, but you also need to think about the profile — that is, how boards are machined. Feather-edge and shiplap are two popular options.

Feather-edge is a more traditional cladding profile, with tapered boards that overlap. It’s associated with a rugged, rustic, rural look, but can still provide a modern look in certain colours.

Shiplap, with its flat surface and subtle curved element and a tongue-and-groove fit, provides a smoother, more refined and uniform look.

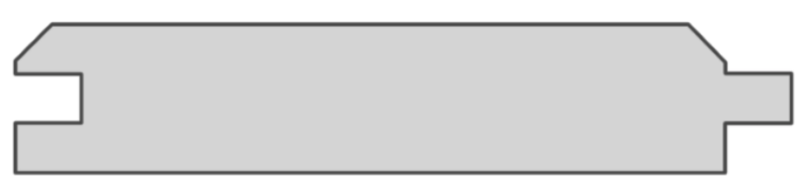

Feather-edge

This profile consists of timber cut diagonally to produce boards that are thicker at one end, tapering towards a thinner end at the other. This is similar to a feather, hence the name.

Once installed, the thicker edge of the boards overlaps with the thinner edge. It is designed to be installed horizontally.

Feather-edge cladding can also be rebated, enabling the cladding to fix flush to the building for enhanced stability. This can enable a reduced amount of overlap on the boards.

This profile is typically associated with rural buildings, so can be useful for imparting a rustic, rugged, rural-inspired and uncomplicated look for your next project, including sheds and barn conversions. It is particularly popular for mimicking the Scandinavian look, particularly when painted black or with a charred look finish.

But despite feather-edge’s countryside connotations, it can still provide a smart façade for a modern building, especially when finished in certain colours — as this Ayous house cladding project we recently worked on shows. Here, feather-edge cladding was factory coated with a RAL 5014 blue colour.

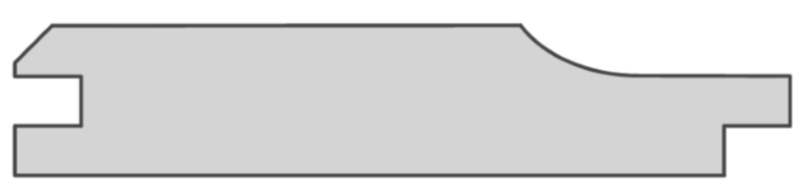

Shiplap

This profile consists of sawn boards that have been machined to have a flat, smooth planed surface with a slightly inward curved shape towards the upper part of the board (also known as the ‘scallop’).

Shiplap profile has a tongue-and-groove fit — a protruding tongue on the top side and a groove on the opposite side, allowing them to fit together to create an interlocking fit. This can help to secure the building, as well as make for potentially easier installation.

Shiplap can be installed vertically or horizontally, with the latter being more popular for this particular type of profile.

The profile’s uniform straight lines and scalloped profile can create a clean, crisp and streamlined look with a subtle shadow line where the boards interlock. This scalloped curve element adds a refined touch, as well as helping rain to run off the structure. This makes it popular for outbuildings like designer sheds, garages, garden rooms and summerhouses.

Shiplap is not to be confused with V-groove. The scalloped curve element is what differentiates these two. As the name suggests, the design of V-groove boards means they create a ‘V’ shape in the cladding surface once fitted together.

Planning a project?

We are a leading UK supplier of quality timber cladding. All of our products are machined on-site by us to a range of designer profiles, including feather-edge, shiplap, V-groove, shadow gap and rainscreen.

We offer cladding in a range of high-performance species, including Western Red Cedar, Siberian Larch, European Oak and thermally-modified options like Thermo-Pine. We also offer factory-finished options: SiOO:X wood protection system, our Colourflex® range of designer colours, and our Chartex® charred-look cladding.

Contact our team to discuss your project.