Timber cladding adds a beautiful, contemporary facade to any building, but as a natural material that’s exposed to the elements, it can change over time.

Under outdoor exposure, wood undergoes a noticeable aesthetic change – it slowly turns a silvery-grey colour.

How (& why) timber cladding changes colour and appearance outdoors

Timber’s colour transformation is caused by the sun’s ultraviolet radiation breaking down lignin, a component in the wood. This lignin is then washed away by moisture to leave behind exposed cellulose, which is a grey colour.

The process, called photodegradation, is essentially just a surface phenomenon. It doesn’t mean that the wood is decaying or rotting in any way whatsoever.

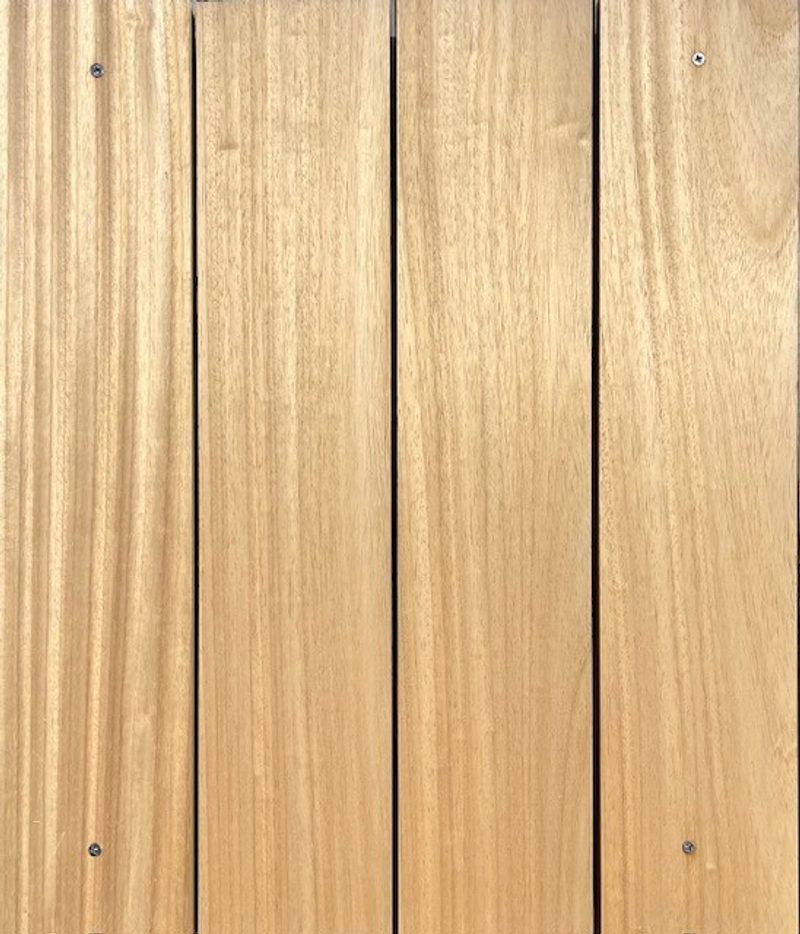

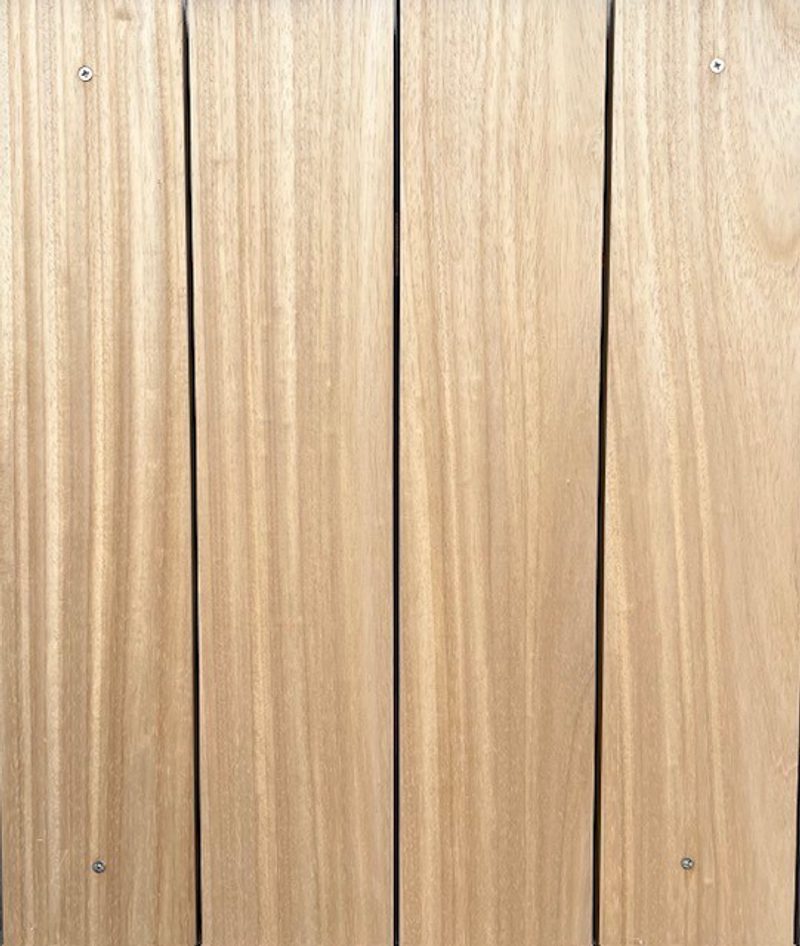

You can see how untreated timber cladding is stripped of some of its original colour in as little as three months. This process can be uneven at first, but eventually the entire surface will weather to the same colour.

Professional pre-finished solutions such as SiOO:X can help to accelerate this natural greying process and give a more consistent end result.

Based on silicone nanotechnology, SiOO:X provides protection against the elements and helps the wood to silver off more evenly. These changes will start within weeks, with the wood continuing to transform over 6–8 months to a lighter, brighter grey tone.

Coating solutions like SiOO:X can provide up to 15 years of service life before requiring some maintenance, which is just a simple clean down and reapplication.

If you like the look of grey cladding, don’t miss our project inspiration blog.

Factors affecting how quickly cladding weathers and goes grey

Aspect, location, species, treatments and design all affect how your wood cladding interacts with its surroundings and how quickly this weathering process occurs.

Aspect

In the UK, south-facing cladding tends to weather fastest due to prolonged exposure to direct sunlight. The UV breaks down the wood’s lignin, revealing the grey cellulose.

If your cladding is west facing, it’s likely to bear the brunt of prevailing winds and rain, particularly if it’s in a coastal or elevated location.

North-facing walls are more likely to stay shaded, which slows down the greying process but provides a more uniform result.

Location

Where your property is situated plays a huge role. Projects in the Scottish Highlands or Lake District will contend with high rainfall and strong winds, both of which accelerate weathering.

If you live in a coastal area, salt-laden air can erode any finishes you’ve applied more quickly, which can accelerate the greying process.

Unsurprisingly, a sheltered site in an urban area will see a slower, more uniform greying process.

View project: PAR moulded cladding in Thermo-ayous, coated in our Colourflex Pro preservative solution

Species

The world is home to thousands of types of wood, all coming from different locations. Each species has different density, oil content and natural durability.

High quality, more resinous woods like western red cedar and Siberian larch resist moisture and UV damage longer, which slows the greying process.

Softer, more porous timbers like spruce – a cheaper option typically in home improvement stores – usually weather more quickly.

View project: shadow gap Thermo-ayous timber cladding with FSC certification

Finishes

Finishes act as a protective barrier, sealing the timber’s surface to limit UV penetration and moisture absorption.

There’s an absolutely huge range of products out there, all giving different looks and levels of protection – transparent water-based treatments, penetrating oil-based semi-transparent stains, even professional factory coatings (like SiOO:X).

Even with a finish, cladding is still likely to go grey, however – but this process is dramatically slowed down. We’ve actually written a full guide on the treatment options available for timber cladding.

Bear in mind that a high-quality timber species does not necessarily need a finish. They only need to be applied if you’re particularly concerned about preventing water damage or would like to maintain the wood’s original look.

Without a finish, expect cladding in outdoor locations to be well on its way to going grey after 12 months.

View project: shadow gap Thermo-ayous timber cladding treated with Teknoclad’s ‘Stone Grey’ coating solution

Design

The shape and form of a building affect how exposed it is to the elements. Features like roof overhangs, for example, will shield the wood from a lot of exterior impact.

View project: Thermo-pine cladding in a structured coal black finish with western red cedar cladding in our Colourflex Natural finish

Orientation can have a small effect, too – vertical cladding is usually better at shedding rain faster than cladding with a horizontal orientation.

We’ve actually written a guide to choosing between vertical and horizontal cladding. Your choice will probably be driven by aesthetics, rather than weathering!

Ready to start your next cladding project?

Or do you still have a few questions?

As a leading UK importer and machinist of a range of quality timber cladding products, we’re perfectly placed to help. For project inspiration, take a look at our case studies.

We also offer a range of factory finishes to ensure long-lasting high performance for your cladding – whether you prefer the original or ‘weathered’ look.

Contact us today